What is Regufoam vibration insulation

Regufoam is an elastomer that consists of a mixed composition of high-quality polyurethane acoustic foam. The denisty types of Regufoam are indicated with a capital D and a number, the lower the number, the lower the density, or rigidity, of this vibration insulation foam. As the density increases, with a maximum of 400 kg/m³, the product can carry bigger loads. The size of the cells becomes smaller and the foam firmer, making it more resistant against resonance. Regufoam is not made of foam particles, but from one piece of polyurethane acoustic foam, this ensures a long lifespan.

Where to use Regufoam vibration insulation?

Regufoam is used to isolate sources that produce vibrations, or resonances, which in turn can set a foundation, a floor for instance, in motion resulting in impact noise, or contact noise. By placing Regufoam between a vibrating source and it's foundation, the material functions as a spring and isolates the source from it's foundation, and thus preventing vibrations to it's foundation.

Regufoam applications

For a few applications we processed Regufoam into a ready-to-use solution for solving various sound problems, such as:

- Fitness equipment

Diminish the thumping noise from a treadmill or the resonance caused by an exercise bike by applying Regufoam Damper Pads. - Washing machines

As for insulating washing machines, we recommend using Regufoam D300 12mm, in pieces of 120 x 120 x 12 mm, as feet under a concrete slab or tile. - (Grand) Piano

By making use of Piano Dampers you diminish contact noise that is caused by a (grand) piano. The Piano Dampers can give the instrument a fuller sound, depending on the type of floor, and reduce resonances to neighbours. - Audio and studio equipment

Light equipment, such as a turntable, gaming console, computer or server case, and loudspeakers can be decoupled using HiFi Damper Pads. These soft vibration dampers are directly applicable underneath a device. No less than 12 pieces in one set!

Which type of Regufoam do I need?

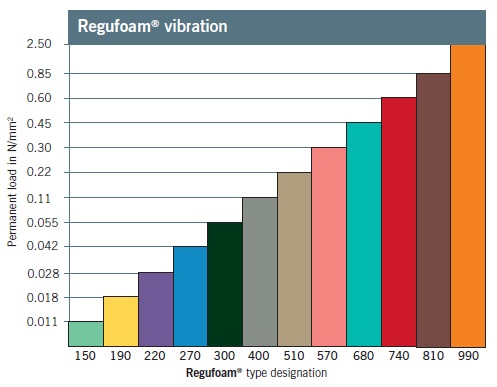

In our Regufoam range you will find various density types of Regufoam and two types of thicknesses, 12 and 25 mm. Density types are D150, D220, D300 and D400 kg/m³. The higher the designation, indicated by a capital D, the tougher the material, and the higher the load it can carry, decouple.

In theory we use for a light devices/sources that vibrate lightly a variant with a low density, D150 or D220, with a thickness of 12 mm. We don't want the source shaking because of it's own motion. More heavy sources that produces vertical frequencies, a treadmill for instance, we need a longer 'spring' so a thicker type with sufficient impact resistance, in this case D220 25mm thick. Sources that have a high RPM, a washing machine of instance, is paced on pieces of Regufoam D300 12mm to prevent violent shaking of the machine/source.

As for simple applications, such as (mobile) air conditioning, treadmills, or swimming pool pumps, and other relatively light equipment, you can use the universal Regufoam Damper Pads. If you use Regufoam vibration insulation in pieces of about 120 x 120 mm you can use this scheme:

- Regufoam type D150 25 mm: 0 up to 100 Kg.

- Regufoam type D220 25 mm: 100 up to 200 Kg.

- Regufoam type D300 25 mm: 200 up to 250 Kg.

Points of attention

When decoupling equipment that has pipes, for water or other liquids, make sure that they are stable and cannot wobble, since this could cause play on the pipes which may cause leakage. Under machines with speed that builds up, Regufoam with a thickness of 12 mm should be applied. A lathe being a case in point, which shouldn't start to wobble but stand steadily. This also applies to machines with a high centre of gravity.

Regufoam vibration insulation in the industrial sector

Apart from simple applications, Regufoam can also be applied to solve more complex sound issues, such as for insulating appliances, foundations of machines, floors, walls and rails from cranes, trains, and trams. As for these applications, you cannot make use of just any type of Regufoam! When you send us all the details regarding your appliance or machine, we will be more than happy to calculate which type of Regufoam and how much material you will need. In this way, you are assured of optimal vibration insulation and a safe functioning of your equipment.

Questions?

Do you have any questions concerning this product or would you like to receive a product sample before making an order? Please feel free to contact us. Information with regards to the various types of Regufoam can be found on our Regufoam product page.

Sound Insulation

Sound Insulation  Soundproofing

Soundproofing  Vibration Isolation

Vibration Isolation  Silent Ventilation

Silent Ventilation  Accessories

Accessories  Thermal & Acoustic Insulation

Thermal & Acoustic Insulation